Tartisan Nickel Corp.

Tartisan Nickel Corp.

As the world looks to add EV’s to the transportation mix to reduce air pollution the demand for battery metals increases. Nickel is one of these battery metals in demand. Tartisan is well positioned to be in this battery market through its projects and investments.

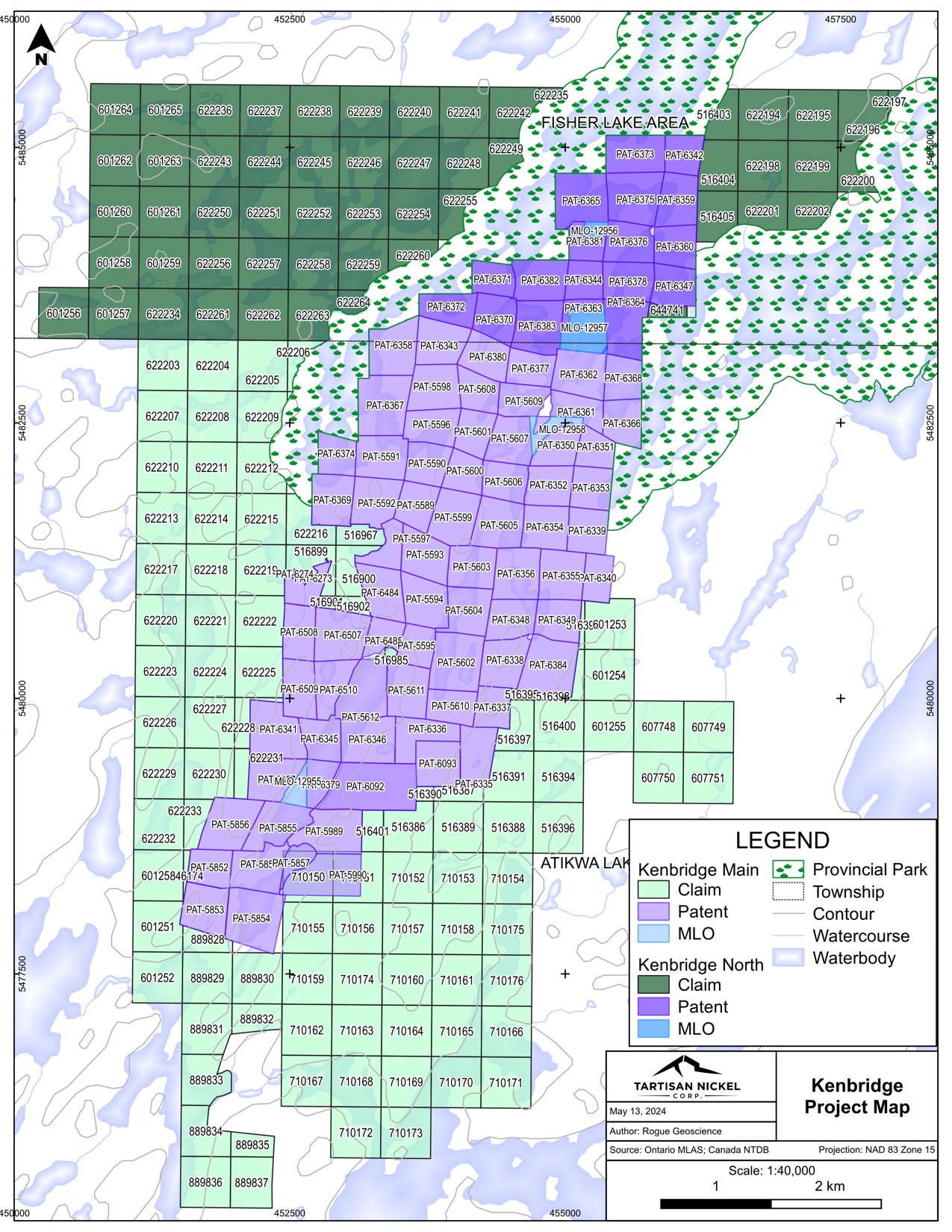

Kenbridge Nickel Project

Kenbridge Nickel Project

The Kenbridge Nickel Project is located in a stable political and mining friendly region (New Gold’s Rainy River Gold Deposit is located 80 km to the south) and has all season road access to within 9 kilometres of the deposit.

The survey picked out the Kenbridge Deposit and has shown the possible extension to the Kenbridge Deposit and three additional trends that relate directly to underlying geology and structure implicit in the Kenbridge Deposit.

Tartisan's Flagship Project

Our Flagship Project

The Latest News

Tartisan Nickel's latest developments